How to Build Tornado Resistant House Kits

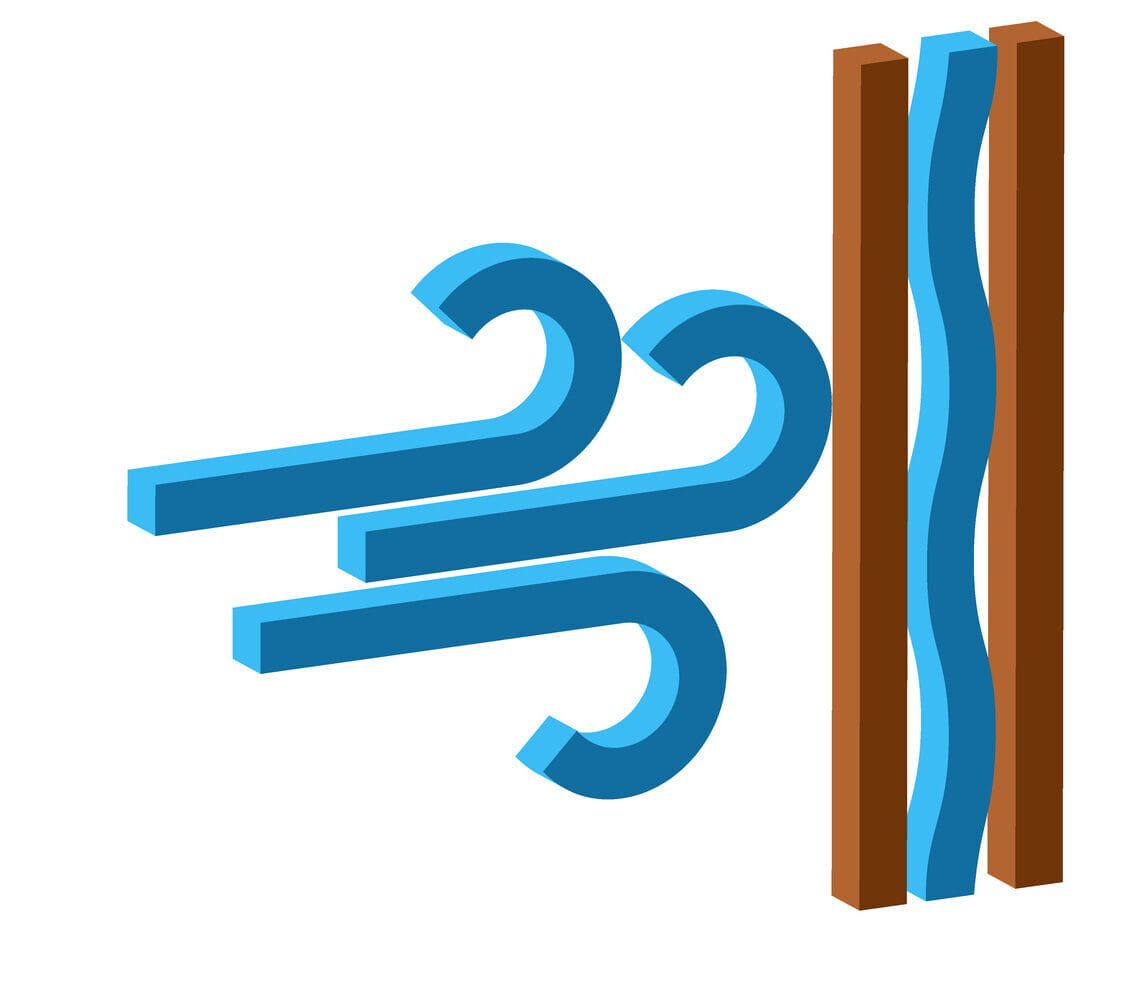

Continuous Load Path Engineering

Tie the roof, walls, and foundation together with reinforced connectors using hurricane ties and anchor bolts so wind forces transfer safely into the ground.

Impact-Resistant Materials

Use laminated glass, reinforced exterior doors, and SIP or concrete walls to stop debris traveling at 100 mph or more.

Structural Insulated Panels (SIPs)

SIP prefab homes provide a rigid shell tested to withstand ~150 mph winds, offering both energy efficiency and tornado resilience.

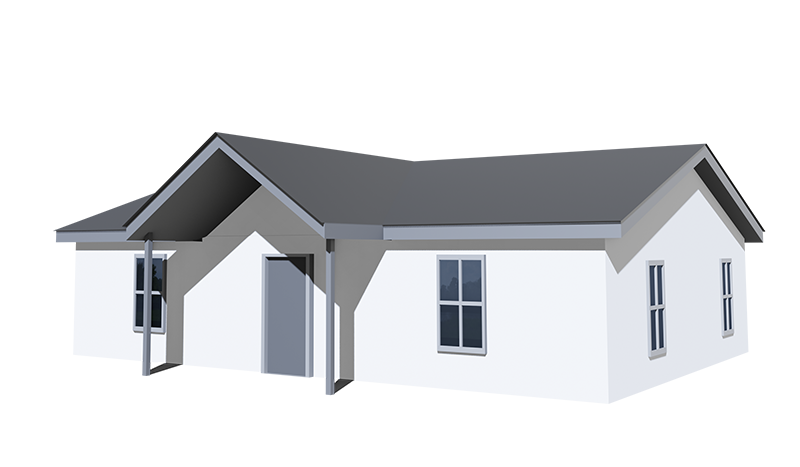

Roof Geometry Matters

Hip roofs outperform gable roofs in high winds; reinforced bracing and metal standing-seam roofing add extra protection.

Safe Rooms and Storm Shelters

FEMA-rated safe rooms built from reinforced concrete or steel provide life-safety protection during EF4–EF5 tornadoes.

Building Code Compliance

Follow International Residential Code high-wind provisions and FEMA guidance to ensure your home meets tornado-resistant standards.

Speed of Construction with Prefab Systems

SIP homes can be dried in within a week and fully built in ~16 weeks, supporting faster community recovery after storms.

Multi-Hazard Benefits

Tornado-resistant designs often add fire resistance, termite protection, mold prevention, and improved energy efficiency.

Alternative Building Methods

Steel-framed, concrete (ICF), dome, and underground homes each offer unique tornado resilience with trade-offs in cost, aesthetics, and construction speed.

Lifecycle Value and Insurance Savings

Resilient homes reduce maintenance, lower energy bills, and may qualify for reduced insurance premiums compared to conventional builds.

Homes That Stands Strong Against Tornadoes

Tornado season brings a level of worry that any homeowner understands. These storms destroy roofs, walls and entire structures every year, with winds that can exceed 200 mph in the strongest events. Even lower-rated tornadoes can peel roofing, blow out windows and send debris through lightly built walls. A house should feel secure, yet during a tornado, many traditional structures offer limited protection.

The desire for a more resilient home is understandable. While no building can be completely tornado-proof, especially in the path of a violent EF5, these extreme events are rare. Most tornadoes fall in the EF0–EF2 range, where better engineering and construction choices can significantly reduce the risk of structural failure.

The focus is tornado resistance. With modern building science and resilient design, you can strengthen weak points, improve the home’s load path and greatly increase its ability to stay intact when hit by severe winds.

The Problem: Tornado Risk and Why Traditional Homes Are Vulnerable

The United States sees more than a thousand tornadoes each year. Many are small, but even those can damage shingles, siding, and windows. A direct hit from an EF2 can push a conventional wood-frame home past its structural limits.

Conventional houses fail because their weak points line up with how wind forces behave.

Lightly attached roofs can lift, walls without proper bracing can rack or overturn, and unreinforced windows and doors can breach under pressure.

Debris impact is another failure mode, especially where wall systems lack structural sheathing or reinforcement.

Without a continuous load path from roof to foundation, the structure can’t transfer uplift and lateral forces effectively.

In stronger storms, collapse or complete loss is common. The most violent EF4-EF5 tornadoes remain uncommon, but they underscore the need for better reinforcement in traditional homes.

The results are expensive and disruptive. Structural loss displaces families, repairs take months, and irreplaceable belongings are often destroyed. More importantly, a home that cannot maintain its structure during extreme winds puts occupants at risk.

Bottom line

Tornadoes pose a persistent risk in many regions, and traditional methods of home construction often fail to account for the forces involved. The next section looks at how modern building science is changing the way homes are built so they stay stronger during severe weather.

The New Science Behind Building Tornado-Proof

Is it possible to design a tornado-proof house? According to structural engineers and building scientists, yes. Decades of research from FEMA, universities, and wind-testing facilities have shown how buildings behave under extreme wind loads. These studies have produced proven strategies for strengthening a home, making it far less likely to fail during a severe storm.

At Texas Tech’s National Wind Institute, researchers have fired 2x4 studs at wall systems to simulate tornado debris, demonstrating that certain assemblies can stop a board traveling at 100 mph.

One core principle is creating a continuous load path. This ties the roof, walls, floors, and foundation together with reinforced connections so wind forces move safely into the ground instead of pulling the structure apart. Engineers achieve this with hardware like hurricane ties, anchor bolts, reinforced wall panels, and other specialized fasteners.

Impact resistance is another requirement. Materials like laminated glass, reinforced exterior doors, and robust wall systems help prevent debris from breaching the home. Concrete, brick and engineered wall assemblies offer much higher resistance to impact than conventional framing.

Florida International University’s Wall of Wind facility exposes full-scale structures to 150 mph winds to measure how they perform. Researchers at Penn State and the University of Florida have tested Structural Insulated Panels (SIPs), finding that they can withstand wind loads of roughly 150 mph.

Building codes have evolved in response. The International Residential Code includes provisions for high winds, and FEMA publishes guidance on safe rooms and resilient construction. The National Storm Shelter Association certifies designs capable of surviving EF5-level impacts. The message is consistent. We have the engineering expertise to build stronger homes.

Resilient construction is also becoming mainstream. From fortified site-built houses to advanced prefab systems, homeowners now have options that barely existed a generation ago. The next section looks at one of the most practical solutions, SIP prefab homes, and how their design supports tornado-resistant performance.

The Solution Spotlight: SIP Prefab Homes for Tornado

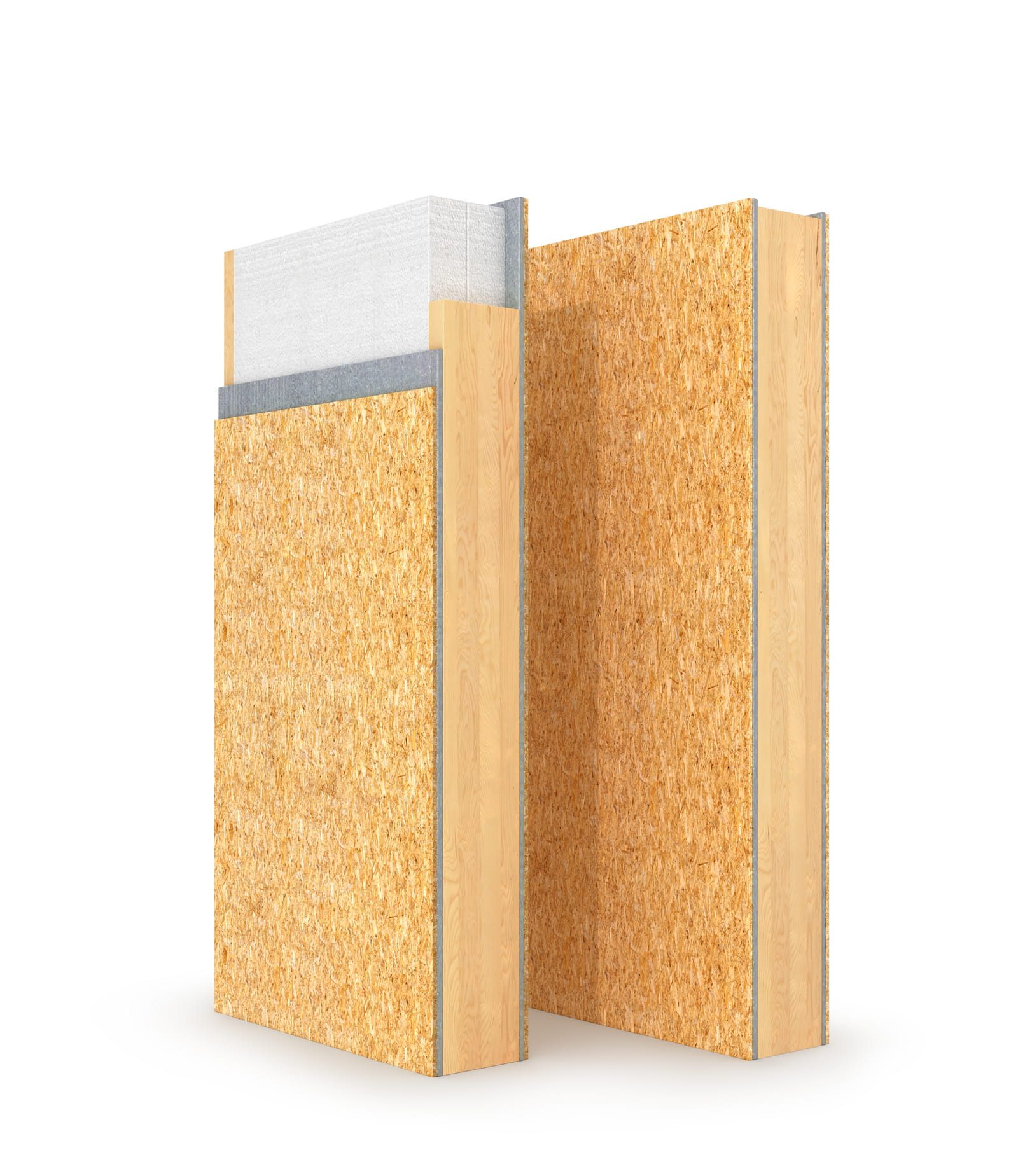

SIPs are large factory-built sandwich panels used for walls, roofs, and floors. They replace conventional framing with a solid, continuous envelope that provides structure and insulation. SIP home kits are already known for energy efficiency, but their strength in high winds is an equally significant benefit.

Built-in Wind Resistance

SIPs form a rigid, continuous load-bearing shell. Testing has shown that well-built SIP structures can withstand wind speeds of up to approximately 150 mph, which covers the wind speeds typically seen in most tornadoes.

Because the panels act as a unified system, forces are distributed across the assembly instead of concentrating on weak points.

This reduces the risk of roof lift or wall failure. Reinforced connectors and properly anchored foundations further improve performance under uplift and lateral loads.

Protection From Debris

Flying debris is one of the most dangerous aspects of a tornado. The solid core and skins of SIPs help prevent penetration where a standard framed wall might fail. Reinforced connectors at panel joints and impact-rated windows and doors complete the protective envelope, improving the home’s ability to remain intact during debris impact.

Speed of Construction

SIP homes go up quickly because panels arrive pre-cut from the factory. The shell can be assembled and under roof in a matter of days, and many SIP builds are dried in within a week. Total construction time typically ranges from 3 to 4 months, compared to 6 to 9 months for stick-built homes. Faster construction keeps materials protected from the weather and speeds up recovery for communities rebuilding after a storm.

Multi-Hazard Performance

SIPs also offer benefits beyond wind resistance. Many panel systems use treated materials that add fire resistance. The solid foam core and OSB skins reduce opportunities for termites and other pests. The tight envelope limits moisture intrusion and reduces the risk of mold growth.

Energy Efficiency and Value

Continuous insulation and minimal air leakage in SIP homes provide excellent energy performance. Many homeowners report significantly lower heating and cooling bills because there are no thermal bridges at studs and fewer gaps for conditioned air to escape over time.

Design and Livability

SIP homes are highly customizable. Manufacturers, like Mighty Small Homes, offer a range of models, custom plan options, and a variety of exterior finishes including wood, brick and stone. Interiors allow open layouts, high ceilings and large windows. SIP construction does not restrict design flexibility; it simply strengthens the underlying structure.

North Carolina SIP House Survives Tornado-Level Storm

A real-world example illustrates this resilience. The Mighty Small Homes SIP house in North Carolina was struck by extreme winds strong enough to uproot large trees. One of those trees fell directly onto the roof.

In a conventional home, a tree of that size could have caused a roof collapse. In this case, the SIP structure remained intact, and the damage was limited to minor cosmetic repairs.

SIP Prefab vs. Hardened Stick-Built: Which Is a Better Path to 150 mph Wind Resistance?

If you already have a conventional wood-frame design you like, or you’re a builder used to traditional methods, you can reinforce a stick-built home for high winds. It’s feasible, but it adds complexity, time, and cost. To reach roughly the same 150 mph wind target that a SIP home achieves by default, a stick-built structure needs multiple upgrades.

Enhanced Structural Connections

Every point where the roof meets the walls and the walls meet the foundation requires reinforcement. Builders install hurricane ties or metal straps at each rafter-to-wall connection to resist uplift. Hold-down anchors or tension rods keep the walls tied to the foundation. This creates a continuous load path, but it’s labor-intensive because almost every truss, corner stud, and joint needs hardware and extra fastening.

Thicker Sheathing and More Fasteners

Standard exterior walls use 7/16-inch OSB or plywood sheathing. Hardened designs often require thicker 5/8-inch material, along with a tighter nailing schedule so the panels can’t pull away under wind pressure. Ring-shank nails or screws may be specified for stronger holding power. Roof decking also becomes thicker with fasteners spaced more closely.

Impact-Rated Openings

Regular windows will usually fail when hit by tornado debris. Hardened builds use impact-rated windows and doors that can withstand a 2x4 travelling around 100 mph. They’re effective but typically two to three times the cost of standard windows. Storm shutters are another option, but they require manual deployment and don’t help if there’s no time to prepare.

Reinforced Roof Design

Roof geometry matters. Hip roofs perform better in high winds than gable roofs. A hardened approach may involve a hip design, additional bracing in the attic, and specifying roof tie-downs. Metal standing-seam roof systems screwed at close intervals offer stronger resistance than shingles, which can peel away in extreme gusts.

Safe Room Addition

Even with significant upgrades, an EF4 or EF5 tornado can exceed the limits of a stick-built structure. Many homeowners add a FEMA-rated safe room built from reinforced concrete or steel. It’s a separate mini-project inside the house and adds cost, but it provides life-safety protection if the rest of the structure fails.

By the time you harden a stick-built home to make it more tornado proof, you’ve usually added 12–25% to the construction cost over a code-minimum build, plus extra weeks of labor and detailed inspections. The result can certainly achieve a ~150 mph performance, but it often ends up costing as much as, or more than, a SIP home that delivers the same strength out of the box.

Comparing Building Methods

Homeowners weighing tornado‑resistant construction often face a choice between upgrading traditional stick‑built designs or investing in SIP prefab systems. Both approaches can reach similar wind‑resistance targets, but they differ in cost, speed, resilience extras, and long‑term value. The table below highlights the key distinctions to help guide decision‑making.

|

Aspect |

Stick‑Built Home |

SIP Prefab Home |

| Structural approach | Requires enhanced load-path design, hardware, thicker sheathing, impact‑rated glazing, reinforced roof systems | Panels inherently provide continuous shear strength and insulation with fewer weak points |

| Cost uplift vs. baseline | +12–25% over standard stick‑built | Often 10–20% higher upfront than code‑minimum stick‑built, but fewer separate upgrades |

| Construction speed | Longer timelines due to added detailing and inspections | Under roof in days. Full build in ~16 weeks or less |

| Wind resistance | Engineered to ~150 mph with extensive upgrades | Engineered and tested to withstand ~150 mph winds (Penn State, University of Florida) |

| Resilience extras | Optional FEMA/ICC-500 safe room adds life‑safety but increases cost | Fire, termite, and mold resistance built into the SIP system |

| Lifecycle value | Higher maintenance and energy loss through framing gaps. Insurance may stay high | Lower energy bills, reduced maintenance, potential insurance savings |

| Design flexibility | Traditional aesthetics, broad builder familiarity | Customizable finishes and layouts. Modern prefab options |

| Community recovery | Rebuilds take longer after storms | Faster rebuilds support community recovery |

Comparison: Other Tornado-Resistant Building Methods

Beyond traditional stick‑built and SIP prefab homes, several alternative construction systems have been engineered to withstand severe wind and debris. Each method brings unique strengths, whether it’s the precision of steel framing, the mass of concrete, the aerodynamic efficiency of dome structures, or the natural protection of earth‑sheltered designs.

At the same time, each option carries trade‑offs in cost, construction speed, aesthetics, and availability. The table below highlights how these approaches compare in terms of resilience, practicality, and long‑term value.

|

Method |

Pros |

Cons |

| Steel-Framed Homes | Extremely strong and non-combustible, no warping or shrinking, excellent high-wind performance, precise engineering, compatible with metal roof systems, pest-resistant, long service life, recyclable. | Higher cost (about $200+ per sq ft), requires specialized labor, thermal bridging unless insulated carefully, corrosion risk without protection, fewer kit/DIY options, limited builder availability. |

| Concrete Homes (ICF or Poured) | Exceptional structural strength with documented survival in EF4+ tornadoes, high debris resistance, non-combustible, excellent soundproofing, high thermal mass, low maintenance, long lifespan, mold and moisture resistance, when properly sealed. | Heavy and slower to build, depends on skilled crews and good weather, typically $180–$250 per sq ft, slightly reduced interior space due to thick walls, harder to modify once built, aesthetic flexibility requires extra finishing. |

| Dome Homes (Geodesic or Monolithic) | Aerodynamic shape sheds wind, strong due to stress distribution, highly energy-efficient, quieter interiors, uses fewer materials for strength, dome kits available, long lifespan with proper maintenance. | Non-traditional appearance may affect resale or HOA approval, curved walls complicate layouts, connecting domes adds complexity; geodesic seams require careful sealing, costs average $150–$200 per sq ft, specialized builders needed. |

| Underground / Earth-Sheltered Homes | Maximum wind and debris protection, highly energy-efficient, extremely quiet, reduced exterior maintenance, excellent fire resistance, blends with landscape, stable year-round temperatures. | Limited natural light without skylights/solar tubes, requires strong ventilation and humidity control, waterproofing and drainage are critical and costly, unsuitable for high water tables, excavation adds cost, enclosed feel if not designed well. |

Case Study: A Real-World Example of Resilience in Action

In March 1998, a tornado struck Clermont, Georgia, destroying several neighboring stick-built homes. One house built with Structural Insulated Panels (SIPs) remained standing. It lost part of its roof shingles but suffered no structural damage, and the family inside was unharmed.

While surrounding homes required full rebuilds, the SIP home needed only minor roof repairs. Its continuous, rigid wall and roof system distributes wind loads effectively, preventing the structural failures seen in the conventional wood-framed houses nearby.

On a community level, homes that stay intact support faster recovery. Fewer displaced families, quicker utility restoration, and less demand on emergency services all contribute to a smoother aftermath when resilient construction is used.

You Can’t Control the Storm, But You Can Build for It

Tornadoes are a persistent hazard, but construction choices can significantly reduce risk. Modern building science offers clear, proven methods for improving performance in high-wind events. Continuous load paths, impact-resistant materials, and engineered systems like SIP prefab kits allow homeowners to build stronger, more resilient structures.

If you’re planning a new build or major renovation, it’s worth involving specialists familiar with high-wind design.

FAQs

No home is completely “tornado-proof,” but modern engineering can create highly tornado-resistant structures capable of withstanding extreme winds and debris.

Reinforced concrete homes, dome structures, and earth-sheltered designs typically offer the highest resistance.

Work with an architect or engineer experienced in high-wind design, choose tested structural components, and ensure proper connections at every stage of construction.

Yes, though retrofits rarely match the strength of a purpose-built resilient design.

This varies by system, but many resilient designs are engineered for roughly 150 mph wind loads.

Some insurers offer discounts for mitigation features, though this depends on policy and location.

Yes. SIP homes have shown strong performance in wind-testing and real events due to their continuous, high-strength panel structure.

Prefab systems like SIP or steel frame kits often outperform traditional stick-built homes because the components are engineered for strength and installed with consistent precision.

In high-risk areas, many experts still recommend including a FEMA-rated safe room for maximum life-safety protection.

Insulated Concrete Forms (ICFs), reinforced masonry, poured concrete, and engineered steel frame systems all offer strong high-wind resilience.