Comparing SIP Homes vs. ICF Homes

When it comes to building energy-efficient homes, SIPs and ICF are two popular modern construction techniques. Both methods offer benefits for would-be home builders, including quick construction, energy savings, and increased durability.

However, it's important to know these two building materials also have distinct advantages and disadvantages that may affect how well they support your goals for building the house.

Here we will explore some of those distinctions, and give you enough information on their advantages and disadvantages to help you decide which method is the better fit for your project.

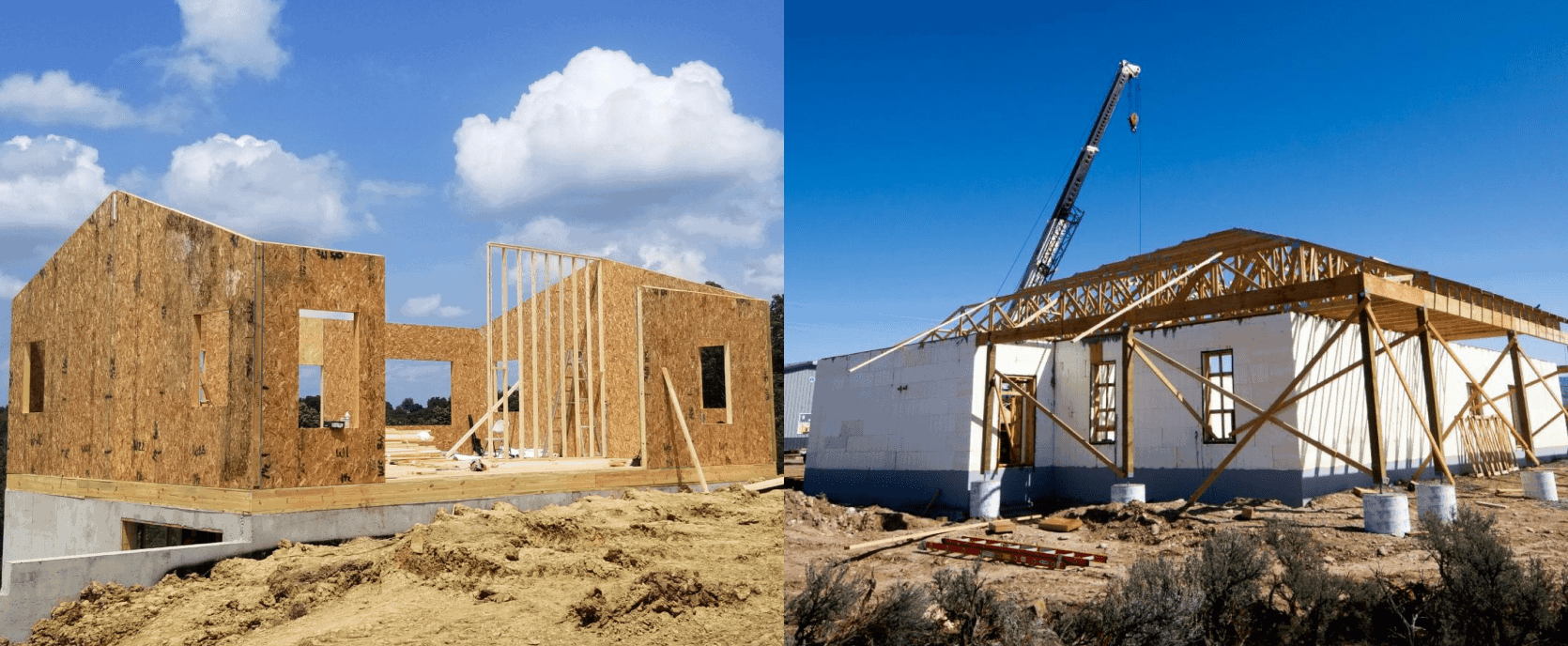

What are SIPs?

SIPs, short for Structural Insulated Panels, are advanced building materials designed to form strong, energy-efficient houses when assembled. SIPs feature a solid foam core sandwiched between two layers of structural board, usually Oriented Strand Board (OSB) – a type of plywood. These panels are prefabricated in our factory, then shipped to your building site for final assembly.

Building a SIP panel home starts with finalizing the floor plans, followed by the manufacturing of the panels according to the design. Surrounded by studs, the foam core in each panel provides excellent insulation, keeping the house warm in winter and cool in summer. The exterior OSB layers give the panels added strength and stability.

At the home site, builders or do-it-your-selvers quickly assemble the panels to form the home's floors, walls, and roof. The panels fit together tightly, creating a sealed, strong, and energy-efficient shell. This process is much faster than the traditional method of building walls for stick-built homes. In fact, our SIP house kits can be under roof in a day or two, and completed in about half the time.

Although prefabricated, SIP homes offer many architectural options. They can be cut and shaped to include unique features like large windows or arched doorways. Without the need for roof trusses, support beams and fewer load-bearing supports, the homes usually have vaulted ceilings and open space for custom floor plans. This flexibility allows homeowners to get the look and feel they want in their homes.

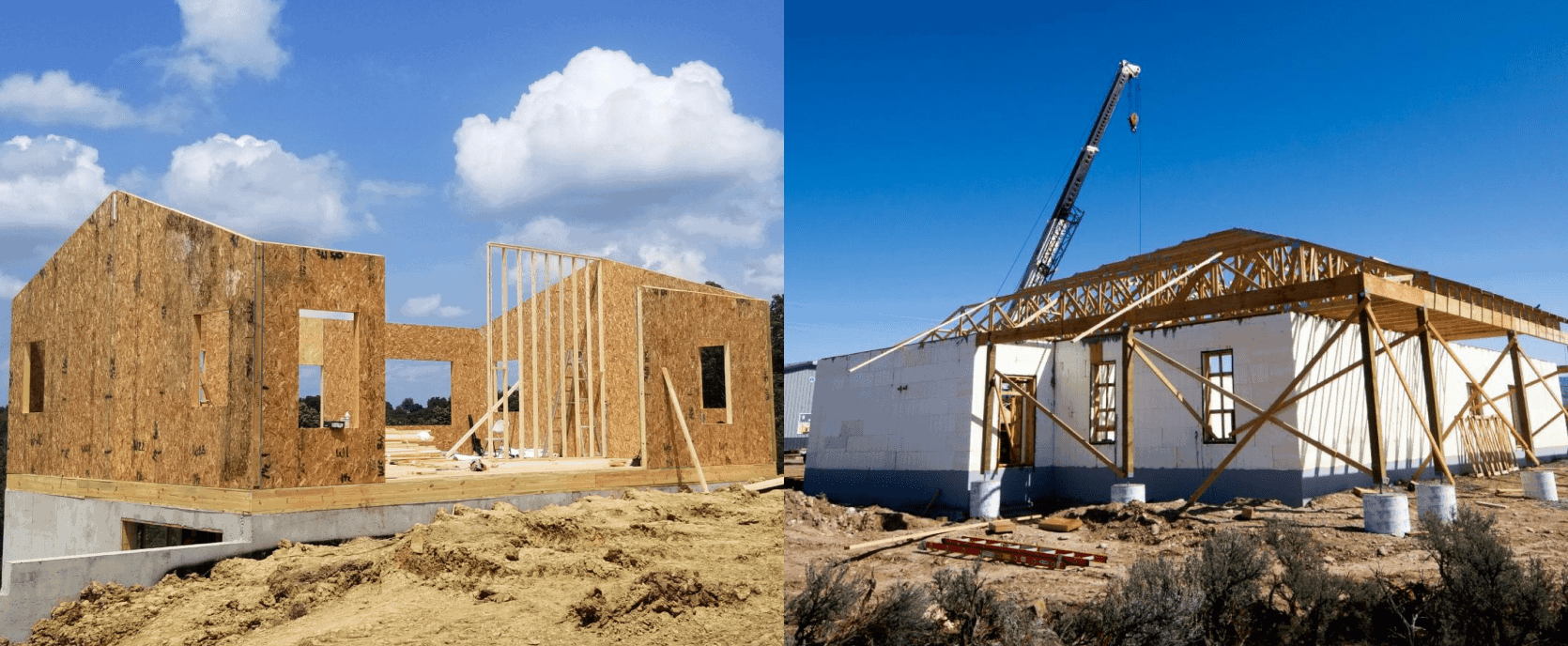

What is ICF (Insulated Concrete Forms)?

ICF homes use Insulated Concrete Forms (ICFs) to create strong, energy-efficient houses. ICFs are made of foam blocks or panels that fit together like Lego bricks. These forms are hollow inside, and they get filled with reinforced concrete to make solid, well-insulated walls.

To build an ICF home, builders first assemble the foam forms on the building site. Workers stack the forms to create the walls, making sure they fit tightly together. They often add steel rebar inside the forms to strengthen the poured concrete walls. Once everything is in place, builders pour concrete to fill the hollow spaces between the foam.

ICF homes are strong and energy-efficient, but they have some design limitations. For example, the thick walls can limit some customization options.

Comparing Advantages and Disadvantages

Pros & Cons of SIPs Homes |

|

|

Pros |

Cons |

|

|

Pros & Cons of ICF Homes |

|

|

Pros |

Cons |

|

|

Key Differences Between SIPs and ICF Houses

Both home-building techniques offer energy efficiency and durability, but they differ in construction methods, materials, performance characteristics, and the building skills required.

Total Build Costs*Including cost of shell, skilled labor, and exterior finishing |

||

|

SIPs |

ICFs |

|

|

1,200 sq. ft. House |

$350,000 |

$450,000 |

Materials & Structures |

||

|

Composition |

SIPs are made of a rigid foam core sandwiched between two layers of oriented strand board (OSB) |

ICFs consist of interlocking foam blocks or panels that are hollow and filled with reinforced concrete |

|

Construction |

Prefabricated in a factory to specific sizes and shapes, then transported to construction site |

The forms are assembled on-site, filled with rebar for reinforcement, and then poured with concrete to create solid walls |

Performance |

||

|

Insulation (Thermal) |

Provide excellent insulation due to the continuous foam core |

High insulation levels with the added benefit of thermal mass from the concrete, which helps maintain stable indoor temperatures |

|

Insulation (Sound) |

Provides good sound insulation |

Excellent soundproofing due to the thick concrete walls |

|

Durability |

Strong and structurally sound, suitable for walls, roofs, and floors |

Extremely durable, resistant to severe weather, fire, moisture, and pests due to the solid concrete core and foam insulation |

Construction Time & Cost |

||

|

Time |

Faster construction due to prefabrication, leading to shorter on-site assembly times |

More labor-intensive and time-consuming due to on-site assembly and concrete pouring |

|

Cost |

Significantly less costly than ICF and will save on labor costs due to quicker assembly |

Higher initial costs for materials and construction; estimated up to 3 times more than SIP construction |

Applications & Flexibility |

||

|

Applications |

Ideal for residential and light commercial buildings where speed of construction and high energy efficiency are priorities |

Suitable for both residential and commercial buildings, especially in areas prone to extreme weather conditions |

|

Flexibility |

Limited on-site flexibility due to prefabrication; changes in design after manufacturing can be difficult and costly. Panels can be moved to remote building sites. |

Getting concrete trucks to remote building sites can be a challenge. |

Environmental Impact |

||

|

Waste |

Less waste during construction due to prefabrication |

Minimal construction waste due to the use of reusable forms |

|

Sustainability |

Panels use renewable wood resources for their structural OSB facings. Producing panel core consumes 24% less energy than fiberglass insulation of equivalent R-value |

Concrete production has significant environmental impacts, including energy consumption, and particulate and greenhouse gas emissions. |

Construction Method |

||

|

Construction |

Factory manufactured off-site, allowing for precise dimensions and quick assembly |

Once the forms are in place and reinforced with rebar, concrete is poured into the hollow forms, creating a solid, continuous wall. |

|

Assembly |

Panels are joined together using splines, adhesives, and mechanical fasteners. Openings for windows and doors are pre-cut. |

Assembled on-site with foam blocks or panels stacked to form the shape of the walls |

Decide with Confidence

Ultimately, deciding between SIPs panel and ICF homes hinges on your goals and home requirements. It's important to explore both options, including visiting model homes and consulting experts, to ensure your decision aligns with your needs and vision for your new home.

SIPs homes offer significant advantages like energy efficiency, quick assembly times, and cost minimization. Their ease of estimating total costs, compatibility with other materials, and design versatility, including optional lofts without roof trusses, make them appealing. However, they are prone to moisture damage if not properly sealed and can be difficult and expensive to modify post-fabrication.

ICF homes are known for durability and resistance to fire, moisture, and rot. Their thick walls provide superior soundproofing and energy efficiency, making them ideal for warmer climates and long-lasting structures. However, ICF homes are more expensive than SIPs and traditional stick-built homes, and their wall thickness can limit design options and reduce usable square footage. Additionally, ICF construction requires skilled professionals and is more labor-intensive and time-consuming.

Seeking Expert Guidance

Making the right housing decision is an important step in securing your future, comfort, and happiness. Reputable home builders, like Mighty Small Homes, take the time to help individuals navigate housing decisions.

Our experienced professionals provide you with personalized advice, answer your questions, and offer insights into the intricacies of panelized and mobile homes. Contact our helpful experts to get started today.

Related Articles

FAQs About ICF and SIP Homes

The construction process with structural insulated panels involves prefabricating the panels in a factory to specific dimensions. The panels are then transported to the building site, where they are quickly assembled using splines, adhesives, and mechanical fasteners to form the building's shell.

Yes, SIPs can be used for walls, roofs, and floors. They provide a versatile solution for creating a complete building envelope that is strong and energy-efficient.

SIPs are environmentally friendly due to their energy efficiency and the use of renewable wood resources for the OSB facings. The manufacturing process also consumes less energy compared to other insulation materials like fiberglass.

Yes, many homeowners choose to build SIP homes themselves due to the simplicity of the assembly process. However, to ensure proper installation, it’s important to have a good understanding of the construction techniques and to work with experienced professionals when needed.

Yes, SIP homes are generally cheaper to build than ICF homes. Here are the key reasons:

Material Costs: SIPs are prefabricated, reducing waste and costs compared to the resource-intensive ICF construction, which uses significant amounts of concrete and rebar.

Construction Time: SIPs are quicker to assemble due to precise manufacturing, leading to lower labor costs and shorter construction timelines.

Labor Costs: The faster assembly process for SIPs requires less labor, whereas ICF construction is more labor-intensive.

Energy Efficiency: Both methods are energy-efficient, but SIPs can achieve similar insulation with less material, reducing costs.

Foundation and Site Preparation: SIPs are lighter than ICFs, potentially lowering foundation and site preparation costs.

Insulated Concrete Forms (ICFs) are construction materials made of interlocking foam blocks or panels that are filled with reinforced concrete to create strong, energy-efficient walls. The foam forms provide excellent insulation, while the concrete adds structural integrity and durability.

ICF homes offer several advantages, including superior insulation, energy efficiency, excellent soundproofing, and resistance to fire, moisture, and pests. The concrete core provides exceptional strength capable of withstanding severe weather conditions.

Yes. Building with ICFs generally incurs higher initial costs due to the materials and labor involved. However, the long-term energy savings, durability, and reduced maintenance costs can offset the initial investment. Additionally, ICF construction can lead to lower utility bills and increased comfort in the home.

While ICFs offer many design options, there are limitations due to the thickness of the walls and the construction process. Customization requires more planning and coordination with experienced professionals.